Why Associated?

Associated with your brand

Our Capabilities

Our Capabilities Body

Despite the recent expansion into our fourth building (and hitting 100,000 square feet across our facilities), we have no space to spare at Associated. We’re proud of our ever-growing fleet of machinery and all of the capabilities that come with them.

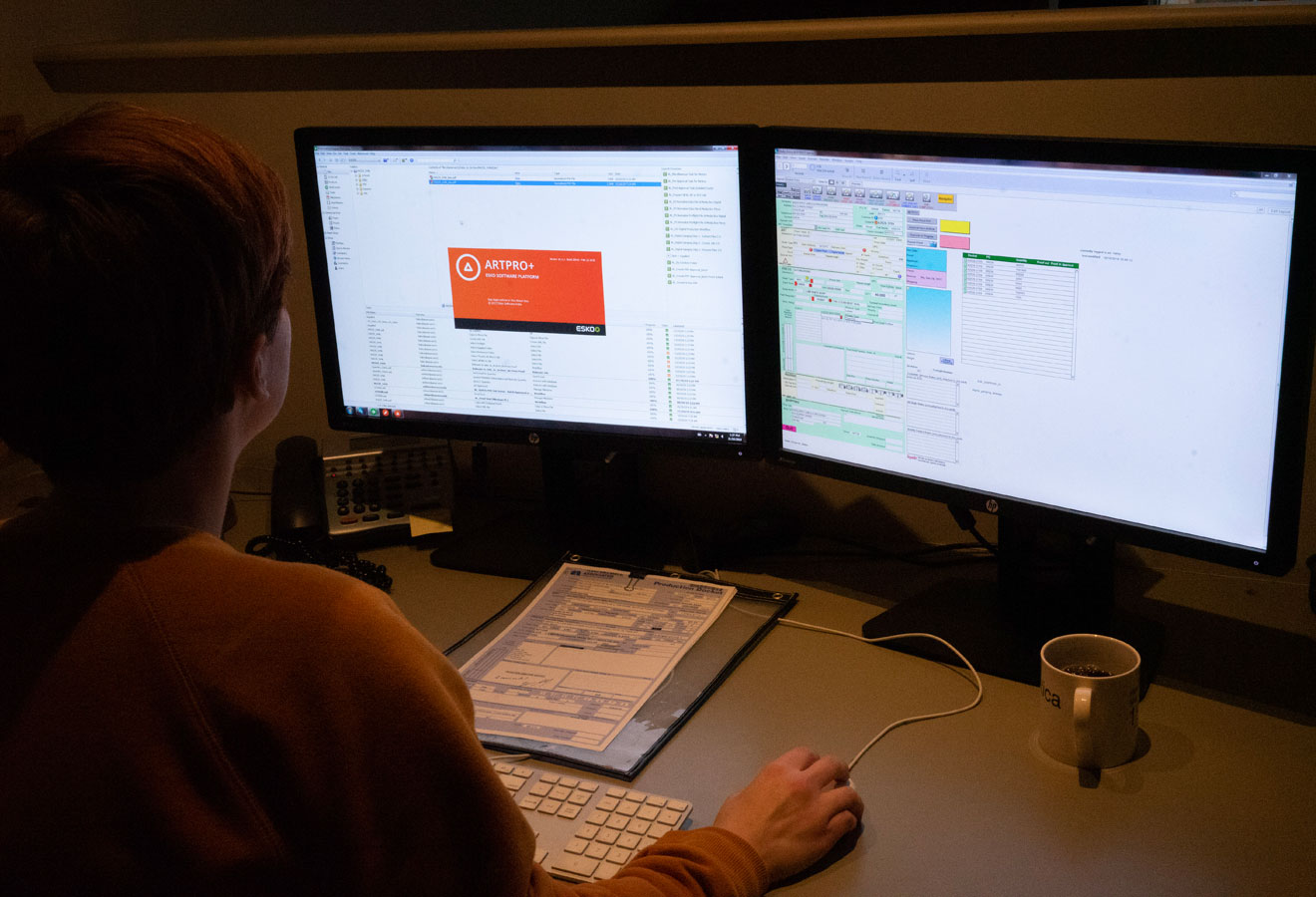

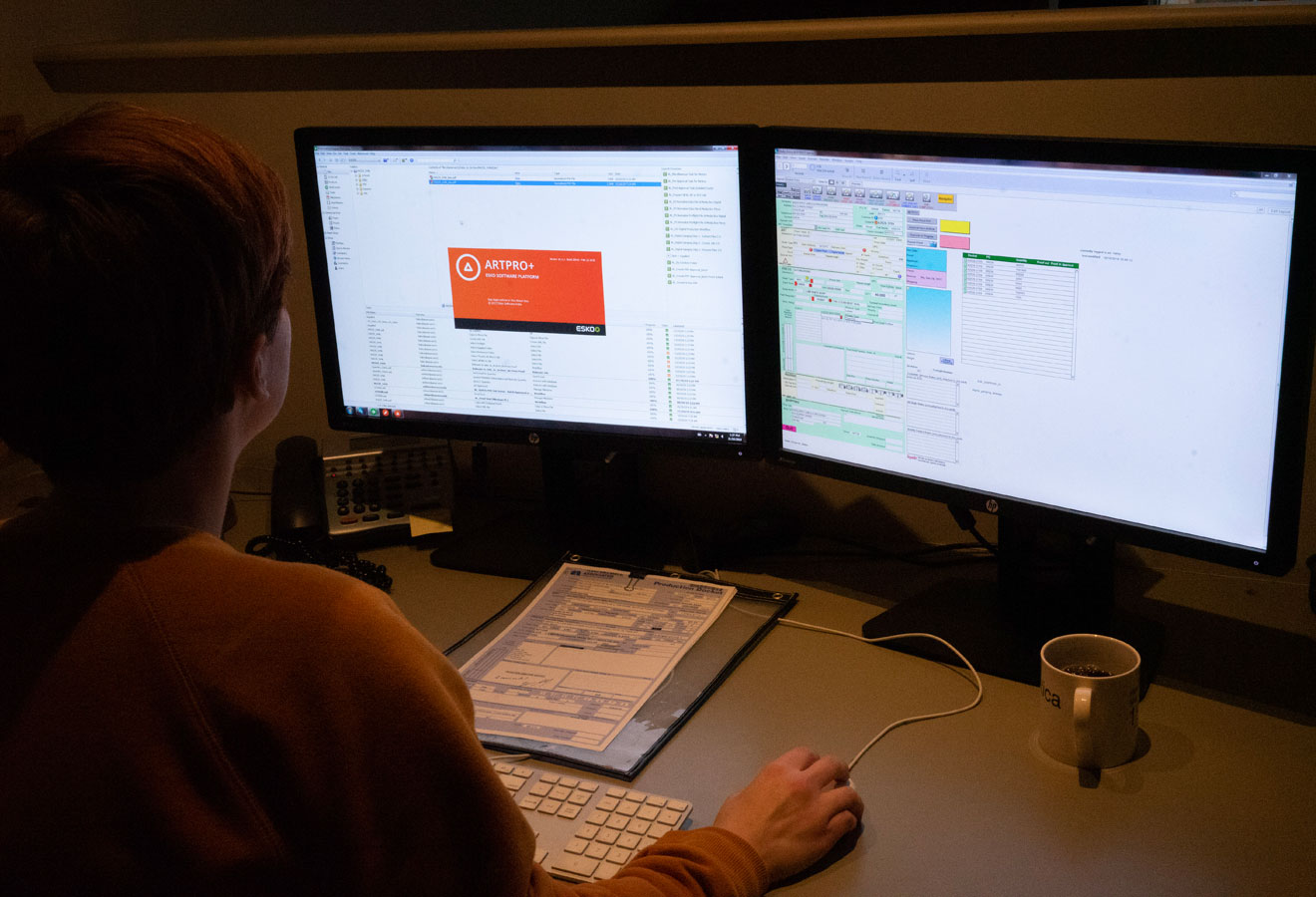

Our pre-press department takes full advantage of our in-house capabilities to create precisely what’s required for your vision. Whatever your needs are, we can work within our existing templates and dielines or create a brand new one specific to your project.

Details

- State-of-the-art equipment and software.

- Extended shift schedule to ensure prepress services from morning to evening.

- Checks for design issues in each art file and works on solutions with customers for optimal press output.

- In-house production of flexographic printing plates to ensure that we have complete control over the accuracy, timing, and quality of every project.

- Can offer WebCenter: an online, web-based application for artwork approval where customers can easily and securely see versions of their artwork for new or revision jobs in progress.

Our pre-press department takes full advantage of our in-house capabilities to create precisely what’s required for your vision. Whatever your needs are, we can work within our existing templates and dielines or create a brand new one specific to your project.

Details

- State-of-the-art equipment and software.

- Extended shift schedule to ensure prepress services from morning to evening.

- Checks for design issues in each art file and works on solutions with customers for optimal press output.

- In-house production of flexographic printing plates to ensure that we have complete control over the accuracy, timing, and quality of every project.

- Can offer WebCenter: an online, web-based application for artwork approval where customers can easily and securely see versions of their artwork for new or revision jobs in progress.

Across our four facilities, we house a range of digital and flexographic printing presses to meet any client's needs. No matter the size of the project, we have an option for you!

- 3 digital printing presses (13"-30"). We can print labels and flexible packaging using the traditional CMYK process as well as our OVG extended colour gamut, which covers up to 97% of the Pantone range.

- 9 flexographic printing presses (10" - 17"). Our presses range from 8-10 colour stations.

- Central Impression flexographic printing press (52"). We have the ability to print 10 colours with this machine.

Inks

- Water-based, UV-based, and solvent-based inks and custom match colors

- Fluorescent and metallic inks

- Automated in-house ink dispensing system

- Industry-leading color matching system which utilizes X-Rite EXACT Spectrometers throughout our facility

- Gloss, satin and matte varnish combinations available in water-based, UV, solvent, and compostable formulations

- Over-laminations available in gloss, clear, and matte film layers

Across our four facilities, we house a range of digital and flexographic printing presses to meet any client's needs. No matter the size of the project, we have an option for you!

- 3 digital printing presses (13"-30"). We can print labels and flexible packaging using the traditional CMYK process as well as our OVG extended colour gamut, which covers up to 97% of the Pantone range.

- 9 flexographic printing presses (10" - 17"). Our presses range from 8-10 colour stations.

- Central Impression flexographic printing press (52"). We have the ability to print 10 colours with this machine.

Inks

- Water-based, UV-based, and solvent-based inks and custom match colors

- Fluorescent and metallic inks

- Automated in-house ink dispensing system

- Industry-leading color matching system which utilizes X-Rite EXACT Spectrometers throughout our facility

- Gloss, satin and matte varnish combinations available in water-based, UV, solvent, and compostable formulations

- Over-laminations available in gloss, clear, and matte film layers

Lamination serves many purposes in the process of creating packaging: to improve the strength of the packaging material and make it resistant to tearing, to create barrier properties that protect the packaging from deteriorating agents and preserve the product it contains, to name a few. With our range of lamination and finishing equipment, array of materials including recyclable, compostable, and biodegradable films, and in-house research and development capabilities, Associated can offer customers the solution they need. We also offer a range of specialty films available for pouch creation, which can offer high barrier protection, sustainable packaging alternatives, and a cost-effective packaging solution with maximum visual impact.

Finishing Equipment

- Various slitter/rewinders

- Ability to do micro hole perforation, macro hole perforation and scoring

- Seamer/inspector for shrink film applications

- Laminating capabilities: solvent-less, solvent, and water-based

- Pouch making machine with optional gussets, zippers, tear notches and hanger holes

- Offline foil stamper with hot foil and embossing capabilities

Lamination serves many purposes in the process of creating packaging: to improve the strength of the packaging material and make it resistant to tearing, to create barrier properties that protect the packaging from deteriorating agents and preserve the product it contains, to name a few. With our range of lamination and finishing equipment, array of materials including recyclable, compostable, and biodegradable films, and in-house research and development capabilities, Associated can offer customers the solution they need. We also offer a range of specialty films available for pouch creation, which can offer high barrier protection, sustainable packaging alternatives, and a cost-effective packaging solution with maximum visual impact.

Finishing Equipment

- Various slitter/rewinders

- Ability to do micro hole perforation, macro hole perforation and scoring

- Seamer/inspector for shrink film applications

- Laminating capabilities: solvent-less, solvent, and water-based

- Pouch making machine with optional gussets, zippers, tear notches and hanger holes

- Offline foil stamper with hot foil and embossing capabilities

As an IFS PACsecure certified facility, Associated takes quality control seriously. With features such as micro perforation, macro perforation, hermetic seals, and many more, we take extra precautions with testing to ensure that all of these functions work perfectly on your packaging.

Quality Control Equipment

- Leak detector used to submerge pouches in water and inflate to check for micro leaks in the seal area

- Tester to detect areas of weak seals or seal creep in pouches

- Airflow reader to measure the amount of air that passes through a micro-perforation

- Microscope used to measure the size and shape of a micro-perforation

- COF tester used to measure the slip of various films, which plays a major role in the machinability of films during processing or post-processing

- Tensile test to determine the bond strength of various adhesives

- Test to determine the scuff resistance of applied lacquer or coatings

As an IFS PACsecure certified facility, Associated takes quality control seriously. With features such as micro perforation, macro perforation, hermetic seals, and many more, we take extra precautions with testing to ensure that all of these functions work perfectly on your packaging.

Quality Control Equipment

- Leak detector used to submerge pouches in water and inflate to check for micro leaks in the seal area

- Tester to detect areas of weak seals or seal creep in pouches

- Airflow reader to measure the amount of air that passes through a micro-perforation

- Microscope used to measure the size and shape of a micro-perforation

- COF tester used to measure the slip of various films, which plays a major role in the machinability of films during processing or post-processing

- Tensile test to determine the bond strength of various adhesives

- Test to determine the scuff resistance of applied lacquer or coatings